WELCOME TO PCCS

Find Your Professional Engineering Solutions Provider in Oil & Gas

If you are seeking a reliable engineering services provider specializing in the oil and gas industry, we are here to assist!

"From engineering excellence to project success: Our expertise powers your progress!"

CONTACT US

Leading the Way in Energy Development and Solutions

PCCS inspired to be the world's leading integrated energy development and solutions provider across various markets. We have demonstrable footprints in crude oil refining, natural gas processing treatments, equipment fabrication, installation, commissioning, operations and maintenance, and above all waste-to energy solutions etc..

With the highly development technology environment and extremely flexible financial background, PCCS prides itself as a leading EPC-OM Contractor with strong portfolio in onshore and offshore solutions for Oil & Gas, Bio-fuel and Petrochemical industry among others. it has become an EPC-OM contractor who can handle the turnkey project and bring the maximum value for the client. PCCS owns a high percentage local content and high efficiency to execute our oil & gas projects, while connecting multinational engineering team and financial resources, in order to diversify our business and achieve a successful and efficient delivery.

Building Global Expertise with Local Solutions

PCCS is based on the production and R&D of PCC, and PCCS invested USD 20 million in Benin City, Nigeria to build a fabrication yard of more than 2,000 square meters, providing localized services such as engineering, design, production, procurement, construction, operation, maintenance and after-sales service.

The purpose of building a fabrication yard in Nigeria is to reduce the country’s dependence on offshore sources for equipment, strengthen Nigeria's local manufacturing advantages, meet market demand, and reduce the country's capital flight level, creating employment opportunities.

R&D Strength and Technologies

Our company has several sets of fully automatic precision separation pilot plants, which can complete high-difficulty purification experiments and research such as electronic-grade polysilicon separation, special gas separation and isomer separation, and can also achieve multi-purpose research and development goals such as reactive distillation. PCC is working with the American FRI Association to build a world-class distillation test center to complete the simulation and pilot of many operating units from distillation to reaction. After completion, it will become the world's most authoritative distillation testing center after FRI's US headquarters.

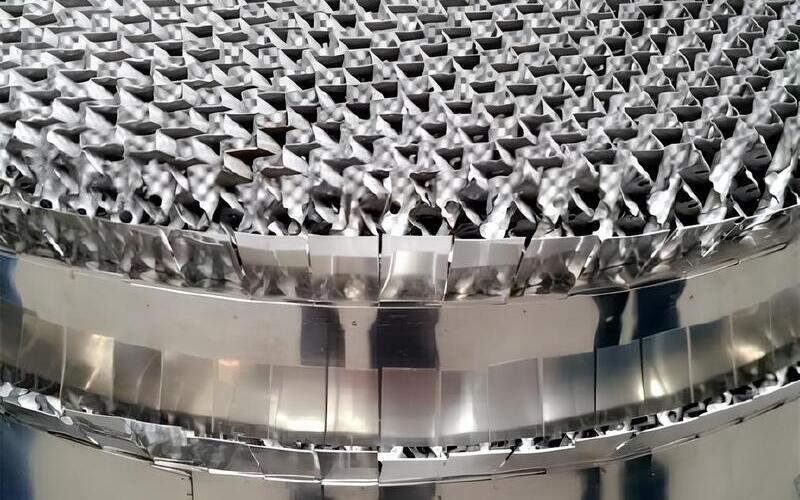

Winpak Packing & Trays Application

After years of continuous innovation, our R&D center has successfully developed many process packages and multiple series of high-efficiency packings and trays. In 2015, PCC became the first Asian company to send its independently developed high-efficiency structured packing (WINPAK patent number ZL201420087293.7) to the American Distillation Research Company (FRI) for testing. According to FRI's authoritative test, the performance of WINPAK packing is more than 30% higher than that of ordinary packing of the same type. After the test results were released to the world, more international chemical giants have learned about our company's technical R&D strength.

_1736233370_WNo_800d500.jpg)

PCCS Partners & Project Cases

After years of development, PCC has become a long-term supplier and technical partner of large enterprises such as PetroChina, SINOPEC, CNOOC, CNASEC, Hangyang, Kaifeng Air Separation and Henan Kaiyuan Air Separation etc.

At the same time, various products are exported to many countries in the world, including Nigeria, Malaysia, France, Italy, Japan, Saudi Arabia, the United States, etc., and have been widely recognized and praised.

Nigeria Edo Refinery

Nigeria Edo Refinery, Capacity: Phase one 1,000BPD, Phase two 5,000BPD. Officially put into production in 2020, the project design meets customer requirements, with a maximum diesel yield of 67% and an average of 55%.

Malaysia Batch Distillation System

Malaysia Batch Distillation System, we adopt modular overall design and construction solutions for fast installation and construction. All indicators meet the design requirements.

Nigeria Koko Refinery

Phase one 3,000BPD, Phase two 30,000BPD. The refinery has two phases, in the first phase, Naphtha, Diesel, Low Pour Fuel Oil, LPG, Propane & Paint Solvent will be produced, with revenues exceeding 2.0 billion USD annually. The OSBL and jetty have been completed, with an estimated full project completion and commissioning date of June 2025.

Phase 2 will increase refining capacity, with revenues exceeding 5.0 billion USD annually, and will commence immediately upon Phase 1 completion. In addition to Phase 1 product slate, Phase 2 will produce: Sulfur, Sulfuric Acid, Vacuum Gas Oil, Base Oil and Bitumen.

Nigeria LPG Gas Processing Plant

Nigeria LPG Gas Processing Plant, Capacity: Phase one 12MMSCFD, Phase two 25MMSCFD. Our designs and products meet customers' requirements.

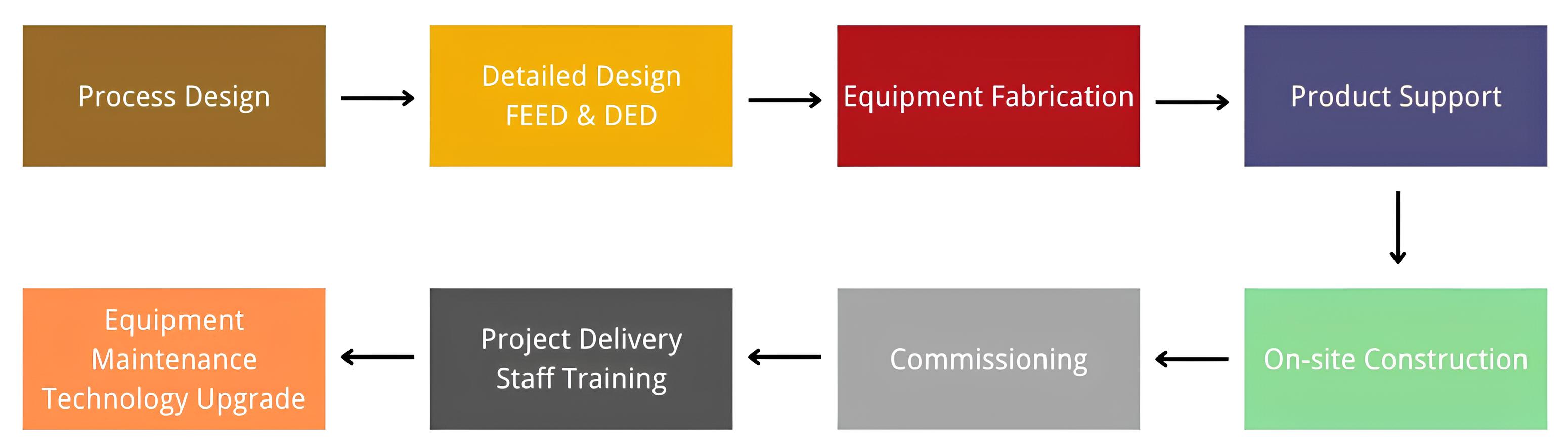

PCCS Customized Solutions Process

PCCS can provide customers with full-process services from new process/new product research and development to process package design, engineering design, product manufacturing integration, on-site construction, commissioning, operation and maintenance, and upgrading and transformation.

Engineering Branch

Engineering Branch

Bankable Feasibility Studies

Bankable Feasibility Studies

Front-End Engineering Design (FEED)

Front-End Engineering Design (FEED)

Detailed Engineering Design (DED)

Detailed Engineering Design (DED)

Procurement

Procurement

Strategic Sourcing

Strategic Sourcing

Supplier Management

Supplier Management

Contract Administration

Contract Administration

Fabrication

Fabrication

Our Fabrication Branch is dedicated to providing world-class fabrication solutions tailored to the specific needs of our clients across diverse industries. We specialize in custom fabrication services, using specialized equipment manufacturing. Our experienced team utilizes advanced techniques and quality materials to deliver solutions that exceed expectations and withstand the rigors of demanding applications.

At PCCS, quality is paramount, and our commitment to excellence is reflected in our rigorous quality assurance and control processes. From initial design and material selection to final inspection and testing, we adhere to the highest industry standards.

We leverage lean manufacturing principles and efficient production processes to optimize workflow and minimize lead times, enabling us to deliver projects on time and within budget. Our focus on continuous improvement and innovation drives operational efficiency, cost-effectiveness, and superior performance, positioning us as a preferred fabrication partner for projects of any scale or complexity.

PCCS Factory Show

_1736152694_WNo_723d480.jpg)

_1736152706_WNo_723d480.jpg)

_1736152716_WNo_723d480.jpg)

_1736153321_WNo_723d480.jpg)

_1736153366_WNo_723d480.jpg)

_1736153714_WNo_723d480.jpg)

_1736153721_WNo_723d480.jpg)

_1736153815_WNo_723d480.jpg)