What is a Modular Refinery?

If you're new to the concept of modular refineries, it's essential to understand the basic principles behind them. Click here to read more about what a Modular Refinery is and how it works.

PCCS Modular Oil Refinery

PCCS Modular Refineries are designed and fabricated in our manufacturing base located in Tianjin, China. As the name implies, all equipment is constructed in modules that are designed to be transported quickly and easily anywhere in the world.

Depending on the refining capacity, Modular Refineries can be designed and constructed with the major part of the work accomplished in our factory in a controlled atmosphere. This greatly improves efficiency and keeps costs low. We do as much of the work in our factory as possible, controlling man hours and material costs through the immediate access afforded by our on-site engineering and design facilities.

For the largest Modular Refineries some components (such as crude distillation columns) are too large to mount on skids and must be shipped separately. Before shipping and while still in our factory, we pre-assemble all of these components directly to the modularized process systems so field assembly is short and efficient.

Our design team will design different solutions based on your specific needs and national policy standards.

Showcasing Our Successful Modular Oil Refinery Projects: Edo Refinery in Nigeria

You can click here to explore examples of our past projects, including the Edo Refinery in Nigeria, a prime example of a modular oil refinery we successfully commissioned.

>> Check Projects: Edo Refinery <<

Below is a showcase of some of our projects of Modular Oil Refinery:

Modular Oil Refinery

| Capacity (Barrel Per Day) | Capacity (Ton/ Year) | Fabrication Period (Months) | Floor Area (㎡) |

| 1,000 BPD | 50,000 | 5 | 30,000㎡-60,000㎡ |

| 3,000 BPD | 150,000 | 6 | 30,000㎡-60,000㎡ |

| 5,000 BPD | 250,000 | 8 | 30,000㎡-60,000㎡ |

| 10,000 BPD | 500,000 | 11 | 50,000㎡-100,000㎡ |

| 20,000 BPD | 1,000,000 | 14 | 50,000㎡-100,000㎡ |

| 30,000 BPD | 1,500,000 | 15 | 50,000㎡-100,000㎡ |

| 40,000 BPD | 2,000,000 | 16 | 50,000㎡-100,000㎡ |

| 50,000BPD | 2,500,000 | 18 | >100,000㎡ |

| 100,000BPD | 5,000,000 | 20 | >100,000㎡ |

EPC Scope of Work for Modular Oil Refinery

| No. | Item | By PCCS | By End-use | |

|---|---|---|---|---|

| 1 | Feasibility Study | Engineering | √ | |

| 2 | Basic Design | √ | ||

| 3 | Detail Design | √ | ||

| 4 | Budgeted Deliverables | √ | ||

| 5 | Local Government Approval and Supervision | √ | ||

| 6 | Purchase Requisitions | √ | ||

| 7 | Parsed MTO | Procurement | √ | |

| 8 | Purchase Order | √ | ||

| 9 | Transportation & Logistics | √ | ||

| 10 | Release to Construction | √ | ||

| 11 | Contracts | √ | ||

| 12 | General Const. Plan | Construction | √ | |

| 13 | Civil Work | √ | ||

| 14 | Piping | √ | ||

| 15 | System Turn-over | √ | ||

| 16 | Start-up & Commissioning | √ | ||

| 17 | Performance Run | √ | ||

| 18 | Turn-Over to End-user | √ |

OSBL & ISBL Scope of Work

| No. | Item | By PCCS | By End-user | |

|---|---|---|---|---|

| 1 | 10000 BPD CDU+VDU | Inside Battery Limits | √ | |

| 2 | Tank Farm | Outside Battery Limits | √ | |

| 3 | Water Supply and Drainage System | √ | ||

| 4 | Power Supply and Telecommunication System | √ | ||

| 5 | System Pipelines | √ | ||

| 6 | Central Control Room | √ | ||

| 7 | Wharf and Berth | √ | ||

| 8 | Vehicle Load-Unload Facility | √ | ||

| 9 | Flare System | √ |

Process Philosophy of Modular Oil Refinery

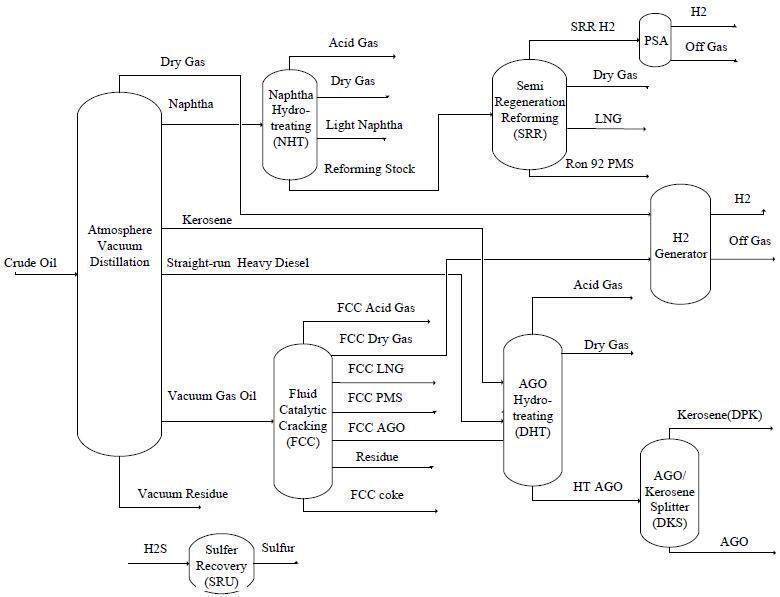

Feedstock will be separated into naphtha, kerosene, straight-run heavy diesel, atmospheric residue oil by ADU. Naphtha from ADU is sent to NHT unit, in which reforming stock is the main product. Reforming stock is rectified by Semi Regeneration Reforming (SRR). PMS and LNG are sent to respective tanks as products. Hydrogen can be regenerated by PSA.

Atmospheric residue oil is sent to vacuum distillation unit (VDU), vacuum gas oil can be produced. Then it is sent to FCC. The FCC dry gas is sent to Hydrogen Generator with dry gas from ADU. FCC AGO, together with kerosene and diesel from ADU, are sent to DHT unit. HT AGO will be produced and sent to AGO/Kerosene splitter where DPK and AGO will be produced. DPK and AGO will be sent to respective tanks as products.

The sulfur will go into the dry gas, LPG, gasoline, and FCC fume, etc. There is sour waste water produced in the processing. The sour gas and sour waste water should be purified to meet the environmental protection standard. The stripped sour waste water will be used as injection water for the electric desalting. The stripped sour gas will be burnt and changed into SO2, then discharged to the atmosphere.

Process Flowchart