Hydraulic Technology CNG Filling Station Daughter Station for NGVs

Description

Reviews

Introduction to Hydraulic CNG Filling Stations

Our Hydraulic Technology CNG Filling Stations are designed for efficient, reliable, and cost-effective refueling of Natural Gas Vehicles (NGVs). These advanced stations provide high-pressure refueling solutions without the need for extensive pipeline infrastructure. With a compact, skid-mounted structure and low power consumption, they are ideal for a range of applications, from urban bus hubs to logistics centers.

| Feature | Description |

|---|---|

| Type | Hydraulic CNG Filling Station |

| Design | Skid-Mounted, Compact Design |

| Power Consumption | Low Power Consumption |

| Refueling Capacity | Up to 50 NGVs (Buses), 200 Trucks (Logistics Centers) |

| Pressure Maintenance | Maintains High Pressure (20.22 MPa) during fueling |

| Installation Requirements | Minimal infrastructure, quick setup |

| Noise Level | Low, Quieter than traditional compressors |

| Customization | Flexible design for specific user needs |

Hydraulic vs. Compressor CNG Filling Stations: Key Differences

| Feature | Hydraulic Technology CNG Station | Compressor Technology CNG Station |

|---|---|---|

| Power Consumption | Low | High |

| Operation Noise | Low, quiet | High |

| Maintenance Requirements | Low | High |

| Refueling Time | Faster, due to consistent pressure | Slower |

| Space Requirements | Compact footprint, skid-mounted | Requires more space for compressors |

| Energy Efficiency | High, low energy usage | Less efficient, high energy usage |

Our Hydraulic Technology CNG Stations are designed to replace existing compressor systems, offering a more efficient, cost-effective solution that requires lower power consumption and reduces operational costs.

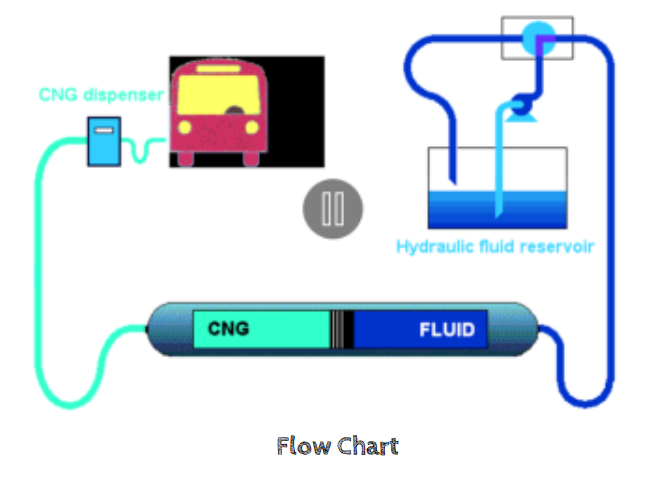

CNG Hydraulic Refueling Substation Process Flow

-

Arrival of CNG Trailer: The CNG trailer arrives at the hydraulic refueling substation.

-

Connection: The trailer is connected to the hydraulic substation skid via high-pressure hoses, including the liquid inlet hose, liquid return hose, and gas outlet hose.

-

Automatic Control: The PLC control system detects low hydraulic pressure and starts the high-pressure hydraulic pump.

-

Pressurization: The liquid medium is injected into the substation cylinder, maintaining 20.22 MPa pressure in the CNG trailer.

-

Refueling: CNG gas flows through the high-pressure gas outlet hose to the CNG refueling machine for vehicle refueling.

This seamless, automated process ensures efficient, high-pressure fueling for NGVs, with a faster refueling time and minimal downtime.

Key Features of Our Hydraulic CNG Stations

-

Skid-Mounted Structure: Compact and easy to install, with minimal land requirements.

-

Low Power Consumption: Reduces electricity usage and operational costs.

-

Stable & Quiet Operation: Operates with lower noise and fewer maintenance issues than traditional compressor systems.

-

Mobile Gas Stations: Can be made mobile, including all necessary systems for on-site refueling.

-

Customizable Design: Tailored to meet specific user needs, ensuring flexibility in application.

Applications of Hydraulic CNG Filling Stations

-

Urban Bus Hubs: Supports up to 50 CNG buses per day for refueling operations.

-

Logistics Distribution Centers: Can refuel up to 200 heavy trucks daily, ensuring operational efficiency.

-

Taxi Shift Change Stations: Achieves rapid refueling times, with 3-minute/shift efficiency for taxi fleets.

Why Choose Hydraulic CNG Filling Stations?

-

Reduced Construction Requirements: The skid-mounted design minimizes the need for extensive infrastructure, leading to faster installation and setup.

-

High-Pressure Maintenance: Ensures consistent high pressure during fueling, speeding up the refueling process.

-

Compact Footprint: Saves space, reducing land and facility costs.

-

Stable Performance: Compared to traditional compressors, hydraulic systems are more stable, quieter, and require fewer maintenance interventions.

Looking for a Custom Hydraulic CNG Filling Station Solution?