PCCS Family

PCCS family consists of PCC , PCCN (PCC Nigeria) , PCCD (PCC Development Limited), PCCF (PCC Fabrication), PCC Gas, Tianjin Sino Oil and Gas, Tianjin Tianji etc.

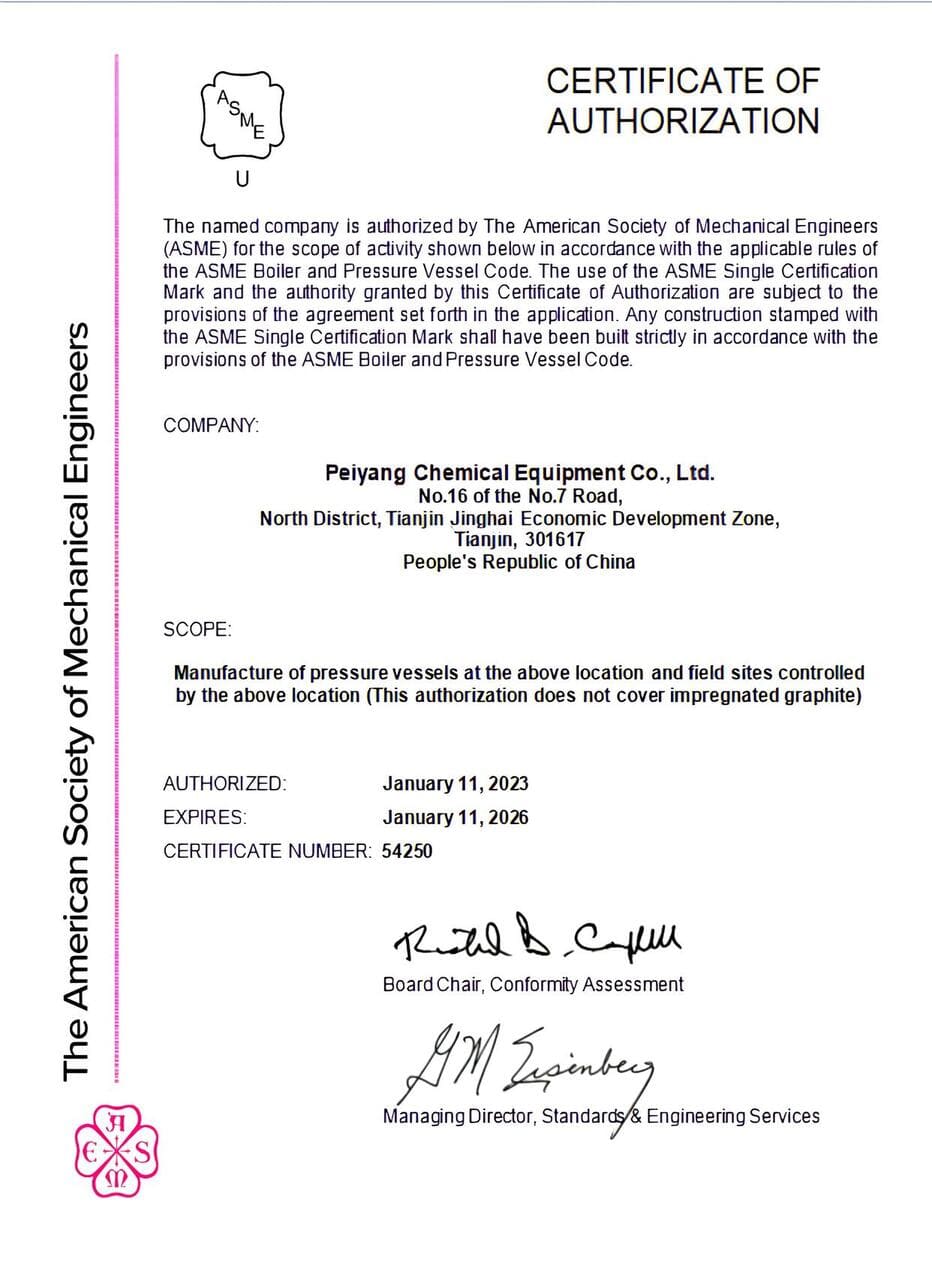

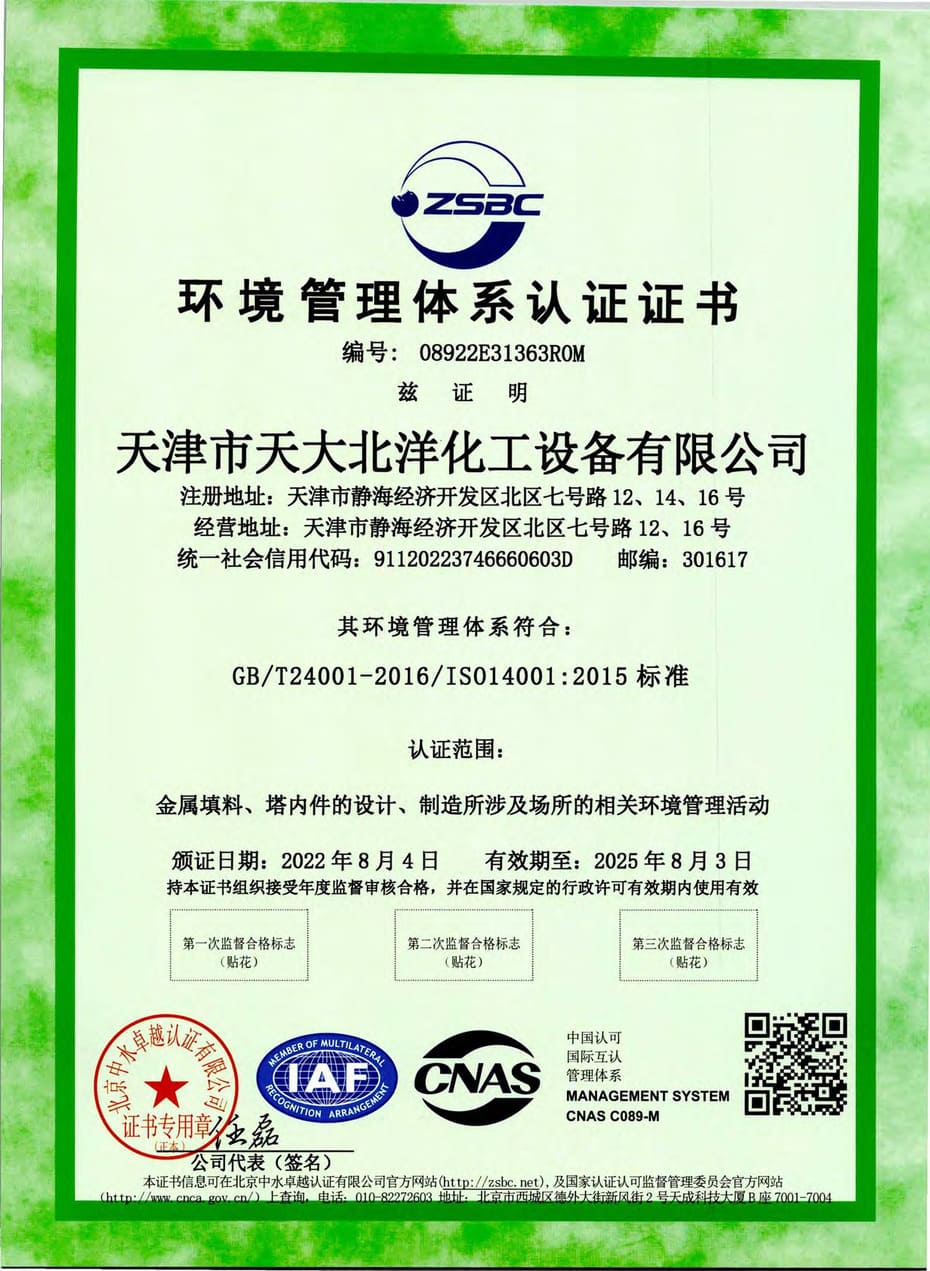

PCC (Peiyang Chemical Equipment Co.,Ltd.), which is a state owned enterprise, and was established in 1993. Tianjin University is the first university in China, called Peiyang University before, it was founded in 1895. As the first university in China it performed as the pioneer of the education. In 1952 the new government restructured all chemical engineering major to Tianjin University. From 1956 to now Chemical engineering school ranked top one in China and ranked top 5 all over the world since 2010. We have 305 professor, 10 national key Lab and 1500+ patents. In C1 technology area about more than 60% of gas plant use our technology.

_1735541657_WNo_1025d577.jpg)

_1735897950_WNo_600d400.jpg)

_1736215223_WNo_932d1274.jpg)

_1736215236_WNo_932d1274.jpg)

_1736215278_WNo_932d1274.jpg)